Introduction to Dalian Metal Plastic Coating Process:

* : * : admin * : 2025-09-29 11:34:47 * : 63

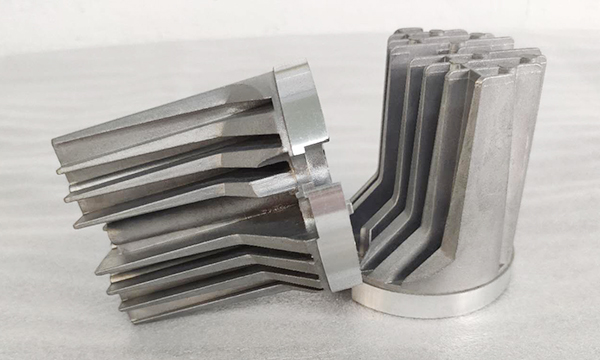

Introduction to Dalian Metal Plastic Coating Process:

Dalian metal coating process: pre-treatment - dust removal - spraying - curing (above 180 degrees).

Plastic coating: roughening the surface of the workpiece - removing dust - spraying - curing or baking paint (below 150 degrees). Dalian Metal Plastic Coating Manufacturer

Except for gold and silver, the properties of other metals are not very stable, and they are more prone to oxidation when exposed to water and air.

In order to make metals more corrosion-resistant, plastic parts are usually sprayed onto them. Plastic spraying is mostly used in the inner layer of metal equipment. After spraying with paint, the metal equipment becomes corrosion-resistant and has a longer service life.

Plastic spraying cannot be used at any time, it has certain construction conditions. Below, we will specifically understand the construction conditions and process of plastic spraying.

Plastic spraying requires people to be patient and follow the process step by step, without omitting any step, and every step should be done almost perfectly.

Especially in terms of details, one must be extra careful, otherwise the effect of spraying plastic parts will not be as good.

The main effect of plastic spraying is its ability to prevent corrosion, which is closely related to its raw materials and determines its scope of use. It is usually used on some metal equipment, and many metal equipment on construction sites have undergone plastic spraying.

previous item: How to operate Dalian metal plastic coating to improve wear resistance layer:

next item: Correct protection analysis of Dalian metal plastic coating:

关闭返回

关闭返回