What are the technologies for surface treatment of metals in Dalian

* : * : admin * : 2024-03-25 9:32:29 * : 90

What are the technologies for surface treatment of metals in Dalian

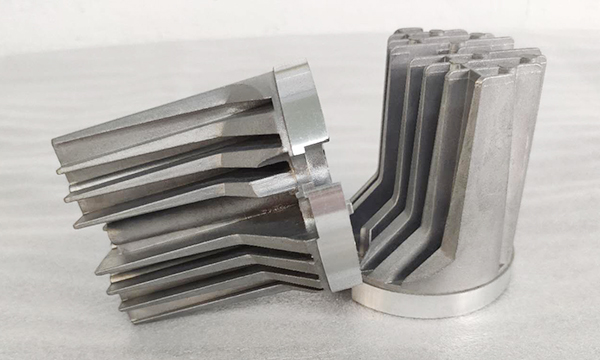

Nowadays, metal surface treatment processes generally include spraying, electroplating, wire drawing, sandblasting, anodizing, passivation, oxidation, polishing, and so on. Among them, the polishing process has a significant impact on the glossiness of metals. There are many polishing processes available now, including manual polishing, vibration polishing, magnetic polishing, electrolytic polishing, chemical polishing, and so on. These polishing methods require the use of sandpaper, polishing paste, vibration grinders, polishing agents, and other products.

For parts of general factory equipment, appropriate surface treatment should be selected according to the required conditions. For example, the general frame is painted, the bolts and nuts are dyed black, the fixed board or base is plated with nickel, and the sliding track or rod can be chrome plated or hard chrome plated according to the required strength. Below are the technologies available for surface treatment of metals in Dalian.

1. Acid pickling and passivation treatment:

It refers to immersing metal parts in acid pickling and passivation solution until the surface of the workpiece turns uniformly silver white to complete the process. Not only is the operation simple, but also the cost is low. The acid pickling and passivation solution can be reused repeatedly.

2. Electrolytic polishing treatment:

This technology refers to electrolytic polishing, also known as electrochemical polishing, which refers to the process of placing a workpiece in an energized solution to improve the surface smoothness of a metal workpiece and produce a glossy finish. Almost all metals can be electropolished, such as stainless steel, carbon steel, titanium, aluminum alloy, copper alloy, nickel alloy, etc., but stainless steel is widely used. By the combined action of positive and negative current and electrolytic polishing solution, the microstructure and geometric shape of the metal surface are improved, and the roughness of the metal surface is reduced, thereby achieving the goal of a bright and flat surface of the workpiece.

3. Oil and rust removal treatment:

For the oil stains, rust stains and other dirt on the surface of the workpiece, it is generally necessary to clean them thoroughly before passivation treatment or electrolytic polishing treatment. Depending on the processing conditions of the workpiece, neutral degreaser (CA-Q02) and stainless steel cleaner (CA-Q03) can be selected.

4. Chemical polishing treatment:

No equipment is required at all, just immerse the metal parts in a chemical polishing solution until the surface is as bright as new to complete the process. For example, copper material chemical polishing, aluminum material chemical polishing treatment, etc.

Electrolytic polishing process, the anode is the polished workpiece, with inactive metal as the cathode. The two poles are placed in the electrolytic cell, and direct current is applied to dissolve the polished workpiece of the anode, thereby achieving the removal of surface roughness of the workpiece and achieving good brightness.

previous item: Dalian Metal Surface Treatment covers a wide range of industries

next item: Surface treatment is a process of changing the surface of metal materials:

关闭返回

关闭返回